¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿Nuevo aquí? Regístrate

¿No tienes una cuenta? Únete gratis

Para publicidad en

¿Interés en convertirse en vendedor? Obtener información

¿Nuevo aquí? Regístrate

Pressure Reducing Valve Turbine Replacement

También conocido como:

Micro Steam TurbineBuy

Made to Order

Manufacturer

New

ISO

Air Freight

Título:

PRV repalcement TurbineNúmero de modelo:

MTSDisponibilidad:

Made to OrderTiempo de entrega (semanas):

52 Weeks

![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Para información sobre productos o servicios, personalización u otras preguntas

Título

PRV repalcement TurbineTambién conocido como

Pressure Reducing Valve Turbine ReplacementNúmero de modelo

MTSDisponibilidad

Made to OrderTiempo de entrega (semanas)

52 WeeksTipo de transacción

BuyPrecio

Request for QuoteCondición

NewMaterial

SteelPeso

Various weights available kgNombre de la marca

KesselsUbicación

IndiaTipo de compañía

ManufacturerGarantía de calidad

ISOEnvío

Air FreightNotas

![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

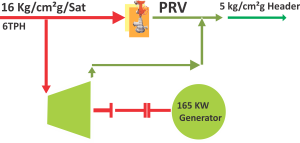

Unlock Energy Efficiency with Kessels API-611 Steam Turbine: The Ultimate PRV Replacement Solution In the dynamic world of industrial applications, energy efficiency is the cornerstone of sustainable operations. Kessels Steam Turbines is proud to offer a groundbreaking solution that replaces traditional Pressure Reducing Valves (PRV) with our robust, reliable, and highly efficient API-611 Steam Turbines. Revolutionizing Energy Efficiency Kessels Single Stage Steam Turbines are tailor-made to handle Saturated Steam at low inlet pressures, harnessing the pressure drop of steam to generate power through the turbine via geared or gearless Turbo Generator set solutions. Choice in Generators for Your Unique Needs Our Turbo Generator sets can be configured with either Induction Generators or Synchronous Generators, catering to the specific requirements of our customers. Energy Recovery at Its Best Kessels Industrial PRV replacement solutions are designed to recover wasted energy by reducing steam pressure through our steam turbines, surpassing the limitations of traditional PRVs. This not only generates valuable power for industrial use but also caters to the process steam requirement of the industry. The result? Drastically reduced operational costs and reduced reliance on the grid and other more expensive power sources. Balancing Act: PRV and Power Generation Kessels Single Stage Steam Turbines are ingeniously designed to enable customers to enjoy the full benefits of a PRV system while simultaneously generating useful power. This equilibrium is achieved without compromising the stability or safety of the system or their setup. Maximizing Power Output For optimum performance, Kessels offers the option of Multiple Valve Operated Steam Turbines. These turbines ensure customers get maximum power output, even at partial loads and varying steam flows. Our valves, available in the Single Stage Steam Turbine range, can be controlled automatically through the special PLC-based governing system provided by Kessels for turbines coupled to Induction Generators. Versatile Powerhouses Kessels API-611 Steam Turbines are versatile, highly efficient, rugged, and robust. They boast single disc one-row and two-row Curtis impulse-type wheels, making them suitable for a wide range of industrial applications. Additionally, these turbines can be retrofitted to any existing boiler setup, making them a versatile choice for various installations. Key Features: Versatile and highly efficient. Single disc one-row and two-row Curtis impulse-type wheels. Retrofittable to existing boilers. Operates efficiently with high exhaust steam pressures. PLC-based control panel with HMI screen for ease of use (optional). Compatible with both Induction and Synchronous Generators. Operates in solo mode or synchronized mode. Can be synchronized with the grid and/or other power sources. Reduces operational costs with a short payback period. Quick startup times and option for complete automatic operation. Choose Kessels for a Sustainable Future Elevate your industrial operations with the Kessels API-611 Steam Turbine, the ultimate PRV replacement solution that combines energy efficiency, reliability, and versatility. Contact us today to discover how our turbine can revolutionize your energy management and lead you toward unprecedented success.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-201EC Extraction Condensing Steam Turbine

Multistage Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Energy Solutions with the Kessels MS-201 EC Extraction Condensing Steam Turbine: Efficiency Perfected In the dynamic world of the oil and gas industry, precision, performance, and sustainability are non-negotiable. Kessels Steam Turbines is proud to introduce the MS-201 EC Extraction Condensing Steam Turbine, a technological marvel that sets new standards in steam turbine excellence. Mastering Extraction Condensing Turbines Extraction condensing turbines are the lifeline of industries requiring a constant pressure steam flow for diverse processes. The MS-201 EC shares structural characteristics with condensing turbines, making it the ideal choice when you need a reliable source of constant pressure steam for your operations. Efficiency at Its Pinnacle What distinguishes the MS-201 EC is its remarkable capability to inject low-pressure steam from the second admission valve chest. This ingenious feature optimizes the utilization of available plant resources to meet power demands, making our turbine an indispensable asset in co-generation scenarios. Steady Power, Unwavering Performance In co-generation settings, where maintaining a consistent power supply despite fluctuations in process steam demands is paramount, the MS-201 EC shines. This turbine ensures your power generation remains steady, providing a rock-solid foundation for your operations. Ultimate Versatility At Kessels, we understand that each industry has unique needs. In some cases, you may require both bleed and controlled extraction steams from the condensing turbine. Our MS-201 EC is designed to meet these demands, offering the flexibility of a bleed cum extraction condensing turbine. Why Choose Kessels? Choosing Kessels Steam Turbines isn't just a business decision; it's a commitment to excellence, innovation, and reliability. Our MS-201 EC Extraction Condensing Steam Turbine embodies these principles, offering you: Unmatched Efficiency: Harness low-pressure steam resources efficiently, reducing energy waste and maximizing productivity. Reliability Beyond Question: Crafted with precision and subjected to rigorous testing, our turbine ensures uninterrupted operations, even in the most demanding industrial environments. Consistent Power Supply: Experience uninterrupted power generation, regardless of variations in process steam demands, ensuring your operations run seamlessly. Exceptional Versatility: Adapt effortlessly to your unique requirements, whether you need bleed or controlled extraction steams, with the confidence that Kessels' expertise provides. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive landscape of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-201 EC Extraction Condensing Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-42 EB Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unleash Power and Precision with the Kessels MS-42 EB Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the high-stakes world of the oil and gas industry, precision and performance are non-negotiable. That's why, at Kessels Steam Turbines, we're proud to introduce our cutting-edge MS-42 EB Multistage Steam Turbine – a powerhouse engineered to redefine excellence in back-pressure turbine technology. Mastering Back-Pressure Turbines Back pressure turbines have been the workhorses of industrial steam applications for decades, and our MS-42 EB takes their capabilities to new heights. Whether it's single-stage or multi-stage options, these turbines serve as the critical bridge between the boiler unit and the process steam header, revolutionizing steam utilization and power generation. Efficiency Redefined Our MS-42 EB Multistage Steam Turbine boasts the hallmark of back pressure turbines: their straight-back pressure nature. This design ensures the efficient harnessing of exhaust steam, meeting process demands with unparalleled precision. Every ounce of electrical power generated is consumed as per the process steam demand, offering unmatched efficiency. Applications Beyond Boundaries At Kessels, we understand that diverse industries have unique demands. That's why our MS-42 EB Multistage Steam Turbine excels in a wide range of applications: Drive Applications: Embrace the power of our turbine in oil and gas operations, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and more. Wherever drive power is needed, Kessels delivers. Power Generation Applications: Elevate your sustainability game by using our turbine to generate electricity, powering generators with clean and efficient steam energy. Bleed Back-Pressure Steam Turbines Our commitment to versatility is evident in the design of the MS-42 EB. With built-in bleed points, uncontrolled extraction vents enable steam extraction within a medium pressure range. This feature proves invaluable in situations where bleeding steam is required at low volume steam demands and when there's a high tolerance for pressure variations. Kessels turbines seamlessly blend the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines When your process steam demand volume is substantial, and you can't compromise on pressure variations, our steam turbines with controlled extraction vents come to the rescue. These turbines operate under intermediate pressure levels, ensuring a steady and reliable steam supply that your operations can depend on. Why Choose Kessels? Choosing Kessels Steam Turbines means choosing a legacy of excellence, innovation, and reliability. Our MS-42 EB Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization and minimize wastage with our precision-engineered turbine. Reliability Redefined: Rigorously tested and built with unwavering precision, the MS-42 EB ensures your operations run seamlessly. Unparalleled Versatility: Adapt to changing needs effortlessly, whether it's drive applications or eco-friendly power generation. Sustainability at Its Core: Harness the power of steam for electricity generation, reducing your carbon footprint and contributing to a greener future. Expert Support: Our team of specialists is always at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-42 EB Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you towards a future of success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-52 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Energy Solutions with the Kessels MS-52 Multistage Steam Turbine: Unleash Power, Precision, and Performance In the ever-evolving realm of steam turbine technology, Kessels Steam Turbines stands as a beacon of innovation and excellence. For the oil and gas industry, where power and precision are paramount, our MS-52 Multistage Steam Turbine is the ultimate solution – engineered to surpass expectations and redefine industry standards. Dominating Back Pressure Turbines Back pressure turbines, available in both single-stage and multi-stage configurations, serve as the vital link between boiler units and process steam headers. These turbines are the backbone of industries that demand a copious amount of steam, revolutionizing the utilization of steam and electricity generation. The Art of Efficiency At the heart of the MS-52 Multistage Steam Turbine is the hallmark of back pressure turbines: the straight-back pressure design. This engineering marvel ensures the seamless harnessing of exhaust steam, matching process demands with unparalleled precision. Every unit of electrical power generated is consumed as per the process steam demand, making it a pinnacle of efficiency. Applications Without Limits Our MS-52 turbine is not just a machine; it's a versatile workhorse ready to excel in various applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Take a giant leap towards sustainability by utilizing our turbine to generate electricity. It powers generators with clean and efficient steam energy, reducing your carbon footprint. Bleed Back-Pressure Steam Turbines At Kessels, we understand that adaptability is key. Our MS-52 turbine comes equipped with built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature proves invaluable when low-volume steam demands and high tolerance for pressure variations are the order of the day. Kessels turbines seamlessly blend the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents come to the forefront. Operating efficiently under intermediate pressure levels, these turbines ensure a steady and reliable steam supply that your operations can depend on. The Kessels Advantage Choosing Kessels Steam Turbines is more than a business decision; it's a choice of a partner committed to your success. Our MS-52 Multistage Steam Turbine embodies our unwavering dedication to innovation, performance, and customer satisfaction. Key Benefits of the MS-52 Multistage Steam Turbine: Unparalleled Efficiency: Maximize steam utilization while minimizing waste. Reliability Redefined: Built with precision and rigorously tested to ensure uninterrupted operations. Unmatched Versatility: Adapt effortlessly to changing needs, be it for drive applications or sustainable power generation. A Greener Future: Harness steam power for electricity generation, reducing your environmental impact. Dedicated Support: Our team of experts is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the competitive world of the oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-52 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward a future of success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-32 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Introducing the Kessels MS-32 Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the dynamic world of industrial steam turbines, efficiency, reliability, and flexibility are paramount. At Kessels Steam Turbines, we understand the unique needs of the oil and gas industry, where the demand for steam is relentless. That's why we are proud to introduce our MS-32 Multistage Steam Turbine – the pinnacle of back-pressure turbine technology. The Power of Back Pressure Turbines Back pressure turbines have long been a cornerstone of industrial steam applications, and they come in both single-stage and multi-stage options. These turbines serve as the vital link between the boiler unit and the process steam header. In environments where a copious amount of steam is required, back pressure turbines shine. Straight-Back Pressure for Maximum Efficiency What sets back pressure turbines apart is their straight-back pressure nature. This design allows for the efficient utilization of exhaust steam to meet process demands. The electrical power generated during the process is consumed precisely as needed, making it an energy-efficient choice. Applications Galore Our MS-32 Multistage Steam Turbine is a versatile powerhouse, ideally suited for a wide range of applications: Drive Applications: Commonly employed in the oil and gas industry, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and many more. Power Generation Applications: Utilized to generate electricity by powering generators, offering a clean and sustainable energy solution. Bleed Back-Pressure Steam Turbines For scenarios where controlled extraction of steam within a medium pressure range is necessary, our turbines come equipped with bleed points. This feature allows for steam extraction at low volume steam demands, making it perfect for applications with high tolerance for pressure variations. Extraction Back-Pressure Steam Turbines When the process steam demand volume is substantial, and tolerance for pressure variations is minimal, our steam turbines with controlled extraction vents step up to the plate. Operating under intermediate pressure levels, they ensure a consistent and reliable steam supply. Why Choose Kessels? When you choose Kessels Steam Turbines, you're choosing more than just a product – you're choosing a legacy of excellence. With a history spanning decades, we have continuously pushed the boundaries of steam turbine technology. Our MS-32 Multistage Steam Turbine is a testament to our unwavering commitment to innovation, performance, and customer satisfaction. Unmatched Benefits of the MS-32 Multistage Steam Turbine: Energy Efficiency: Our turbines maximize the use of exhaust steam, minimizing wastage and lowering energy costs. Reliability: Built with precision and rigorously tested, the MS-32 ensures uninterrupted operations, even in demanding environments. Versatility: From drive applications to power generation, this turbine adapts to your needs with ease. Eco-Friendly: Harnessing the power of steam for electricity generation reduces carbon emissions, contributing to a greener future. Responsive Support: Our team of experts is always at your service, ready to assist with installation, maintenance, and troubleshooting. Upgrade to Excellence Today In the competitive world of the oil and gas industry, every advantage counts. Make the smart choice by upgrading to the Kessels MS-32 Multistage Steam Turbine – the epitome of efficiency, reliability, and sustainability. Contact us today to learn more about how our turbine can revolutionize your operations and propel your success into the future. Your journey to unparalleled performance starts here, with Kessels Steam Turbines.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-32 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Introducing the Kessels MS-32 Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the dynamic world of industrial steam turbines, efficiency, reliability, and flexibility are paramount. At Kessels Steam Turbines, we understand the unique needs of the oil and gas industry, where the demand for steam is relentless. That's why we are proud to introduce our MS-32 Multistage Steam Turbine – the pinnacle of back-pressure turbine technology. The Power of Back Pressure Turbines Back pressure turbines have long been a cornerstone of industrial steam applications, and they come in both single-stage and multi-stage options. These turbines serve as the vital link between the boiler unit and the process steam header. In environments where a copious amount of steam is required, back pressure turbines shine. Straight-Back Pressure for Maximum Efficiency What sets back pressure turbines apart is their straight-back pressure nature. This design allows for the efficient utilization of exhaust steam to meet process demands. The electrical power generated during the process is consumed precisely as needed, making it an energy-efficient choice. Applications Galore Our MS-32 Multistage Steam Turbine is a versatile powerhouse, ideally suited for a wide range of applications: Drive Applications: Commonly employed in the oil and gas industry, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and many more. Power Generation Applications: Utilized to generate electricity by powering generators, offering a clean and sustainable energy solution. Bleed Back-Pressure Steam Turbines For scenarios where controlled extraction of steam within a medium pressure range is necessary, our turbines come equipped with bleed points. This feature allows for steam extraction at low volume steam demands, making it perfect for applications with high tolerance for pressure variations. Extraction Back-Pressure Steam Turbines When the process steam demand volume is substantial, and tolerance for pressure variations is minimal, our steam turbines with controlled extraction vents step up to the plate. Operating under intermediate pressure levels, they ensure a consistent and reliable steam supply. Why Choose Kessels? When you choose Kessels Steam Turbines, you're choosing more than just a product – you're choosing a legacy of excellence. With a history spanning decades, we have continuously pushed the boundaries of steam turbine technology. Our MS-32 Multistage Steam Turbine is a testament to our unwavering commitment to innovation, performance, and customer satisfaction. Unmatched Benefits of the MS-32 Multistage Steam Turbine: Energy Efficiency: Our turbines maximize the use of exhaust steam, minimizing wastage and lowering energy costs. Reliability: Built with precision and rigorously tested, the MS-32 ensures uninterrupted operations, even in demanding environments. Versatility: From drive applications to power generation, this turbine adapts to your needs with ease. Eco-Friendly: Harnessing the power of steam for electricity generation reduces carbon emissions, contributing to a greener future. Responsive Support: Our team of experts is always at your service, ready to assist with installation, maintenance, and troubleshooting. Upgrade to Excellence Today In the competitive world of the oil and gas industry, every advantage counts. Make the smart choice by upgrading to the Kessels MS-32 Multistage Steam Turbine – the epitome of efficiency, reliability, and sustainability. Contact us today to learn more about how our turbine can revolutionize your operations and propel your success into the future. Your journey to unparalleled performance starts here, with Kessels Steam Turbines.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-201 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Operations with the Kessels MS-201 Multistage Steam Turbine: Unmatched Power and Efficiency In the ever-evolving world of the oil and gas industry, precision and performance are paramount. At Kessels Steam Turbines, we're proud to introduce the MS-201 Multistage Steam Turbine, an engineering marvel that redefines excellence in steam turbine technology. Mastering Back-Pressure Turbines Back pressure turbines are the backbone of industrial steam applications, and our MS-201 Multistage Steam Turbine takes them to an entirely new level. Available in both single-stage and multi-stage configurations, these turbines serve as the critical link between boiler units and process steam headers, revolutionizing steam utilization and electricity generation. Efficiency That Sets a New Standard At the heart of the MS-201 Multistage Steam Turbine lies the essence of back pressure turbines – the straight-back pressure design. This innovation ensures the seamless utilization of exhaust steam, aligning precisely with process demands. Every unit of electrical power generated is consumed as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Boundaries Our MS-201 turbine is not just a machine; it's a versatile powerhouse ready to excel in diverse applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines Kessels understands that adaptability is key. Our MS-201 turbine features built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature proves invaluable when low-volume steam demands and high tolerance for pressure variations are critical. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents shine. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-201 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in substantial cost savings and increased productivity. Reliability Beyond Question: Built with precision and rigorously tested to ensure uninterrupted operations, even in the harshest industrial environments. Unparalleled Versatility: Adapt effortlessly to changing needs, whether for drive applications or eco-friendly power generation, with the confidence that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-201 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-152 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Introducing the Kessels MS-152 Multistage Steam Turbine: Unleash Unprecedented Power and Efficiency In the fast-paced world of the oil and gas industry, where precision, performance, and reliability are paramount, Kessels Steam Turbines proudly presents the MS-152 Multistage Steam Turbine. This engineering marvel is poised to redefine excellence in steam turbine technology, delivering unmatched power and efficiency. Mastering Back-Pressure Turbines Back pressure turbines are the backbone of industrial steam applications, and the MS-152 takes them to an entirely new level. Available in both single-stage and multi-stage options, these turbines serve as the critical link between boiler units and process steam headers, revolutionizing steam utilization and electricity generation. Efficiency Beyond Imagination At the heart of the MS-152 Multistage Steam Turbine is the essence of back pressure turbines – the straight-back pressure design. This innovative engineering ensures the seamless harnessing of exhaust steam, aligning precisely with process demands. Every unit of electrical power generated is consumed as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Limits Our MS-152 turbine is not just a machine; it's a versatile powerhouse ready to excel in diverse applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines Kessels understands that adaptability is key. Our MS-152 turbine features built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature proves invaluable when low-volume steam demands and high tolerance for pressure variations are critical. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents shine. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-152 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in substantial cost savings and increased productivity. Reliability Redefined: Built with precision and rigorously tested to ensure uninterrupted operations, even in the harshest industrial environments. Unparalleled Versatility: Adapt effortlessly to changing needs, whether for drive applications or eco-friendly power generation, with the confidence that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-152 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-52 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Energy Solutions with the Kessels MS-52 Multistage Steam Turbine: Unleash Power, Precision, and Performance In the ever-evolving realm of steam turbine technology, Kessels Steam Turbines stands as a beacon of innovation and excellence. For the oil and gas industry, where power and precision are paramount, our MS-52 Multistage Steam Turbine is the ultimate solution – engineered to surpass expectations and redefine industry standards. Dominating Back Pressure Turbines Back pressure turbines, available in both single-stage and multi-stage configurations, serve as the vital link between boiler units and process steam headers. These turbines are the backbone of industries that demand a copious amount of steam, revolutionizing the utilization of steam and electricity generation. The Art of Efficiency At the heart of the MS-52 Multistage Steam Turbine is the hallmark of back pressure turbines: the straight-back pressure design. This engineering marvel ensures the seamless harnessing of exhaust steam, matching process demands with unparalleled precision. Every unit of electrical power generated is consumed as per the process steam demand, making it a pinnacle of efficiency. Applications Without Limits Our MS-52 turbine is not just a machine; it's a versatile workhorse ready to excel in various applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Take a giant leap towards sustainability by utilizing our turbine to generate electricity. It powers generators with clean and efficient steam energy, reducing your carbon footprint. Bleed Back-Pressure Steam Turbines At Kessels, we understand that adaptability is key. Our MS-52 turbine comes equipped with built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature proves invaluable when low-volume steam demands and high tolerance for pressure variations are the order of the day. Kessels turbines seamlessly blend the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents come to the forefront. Operating efficiently under intermediate pressure levels, these turbines ensure a steady and reliable steam supply that your operations can depend on. The Kessels Advantage Choosing Kessels Steam Turbines is more than a business decision; it's a choice of a partner committed to your success. Our MS-52 Multistage Steam Turbine embodies our unwavering dedication to innovation, performance, and customer satisfaction. Key Benefits of the MS-52 Multistage Steam Turbine: Unparalleled Efficiency: Maximize steam utilization while minimizing waste. Reliability Redefined: Built with precision and rigorously tested to ensure uninterrupted operations. Unmatched Versatility: Adapt effortlessly to changing needs, be it for drive applications or sustainable power generation. A Greener Future: Harness steam power for electricity generation, reducing your environmental impact. Dedicated Support: Our team of experts is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the competitive world of the oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-52 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward a future of success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-32 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unleash Unprecedented Power with the Kessels MS-102 Multistage Steam Turbine: The Apex of Efficiency and Reliability In the oil and gas industry, where power and precision are non-negotiable, Kessels Steam Turbines proudly presents the MS-102 Multistage Steam Turbine – a true marvel of engineering designed to redefine excellence in the world of steam turbines. Mastering Back-Pressure Turbines Back pressure turbines have long been the cornerstone of industrial steam applications, and our MS-102 Multistage Steam Turbine takes their capabilities to an entirely new level. Available in both single-stage and multi-stage configurations, these turbines are the linchpin between boiler units and process steam headers, revolutionizing steam utilization and power generation. Efficiency Beyond Compare At the heart of the MS-102 Multistage Steam Turbine lies the essence of back pressure turbines – the straight-back pressure design. This innovation ensures the seamless utilization of exhaust steam, aligning perfectly with process demands. Every unit of electrical power generated is consumed precisely as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Boundaries Our MS-102 turbine is not merely a machine; it's a versatile powerhouse ready to excel in an array of applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines At Kessels, we understand that adaptability is key. Our MS-102 turbine comes equipped with built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature is invaluable when low-volume steam demands and high tolerance for pressure variations are essential. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents come to the forefront. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-102 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in cost savings and increased productivity. Reliability Beyond Question: Built with precision and rigorously tested to ensure uninterrupted operations, even in the most demanding environments. Unparalleled Versatility: Adapt effortlessly to changing needs, be it for drive applications or eco-friendly power generation, knowing that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-102 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward a future of unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-42 E Extraction Condensing Steam Turbine

Multistage Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Experience Unmatched Efficiency with the Kessels MS-42E Extraction Condensing Steam Turbine: Your Power and Steam Solution In the fast-paced world of the oil and gas industry, precision, reliability, and efficiency are the cornerstones of success. Kessels Steam Turbines is proud to introduce the MS-42E Extraction Condensing Steam Turbine, a technological marvel designed to exceed your expectations and redefine excellence in steam turbine technology. Mastering Extraction Condensing Turbines Extraction condensing turbines are the beating heart of industries where a constant pressure steam flow is essential for various processes. The MS-42E shares constructional characteristics with condensing turbines, making it the ideal choice when you need a reliable source of constant pressure steam for your operations. Efficiency at Its Finest What sets the MS-42E apart is its ability to inject low-pressure steam from the second admission valve chest, efficiently utilizing available plant resources to meet power demands. This makes our turbine a vital player in co-generation scenarios, where it caters to both the power and steam requirements of your process plant. Steady Power, Unwavering Performance In co-generation settings, where maintaining a consistent power supply despite fluctuations in process steam demands is crucial, the MS-42E shines. This turbine ensures that your power generation remains steady, providing a reliable foundation for your operations. The Ultimate in Versatility At Kessels, we understand that every industry has unique needs. In some cases, you may require both bleed and controlled extraction steams from the condensing turbine. Our MS-42E is designed to meet these demands, offering the flexibility of a bleed cum extraction condensing turbine. Why Choose Kessels? Choosing Kessels Steam Turbines is not just a business decision; it's a commitment to excellence, innovation, and reliability. Our MS-42E Extraction Condensing Steam Turbine embodies these principles, offering you: Unmatched Efficiency: Utilize low-pressure steam resources efficiently, reducing energy waste and maximizing productivity. Reliability Beyond Question: Built with precision and rigorously tested, our turbine ensures uninterrupted operations, even in the most demanding industrial environments. Consistent Power Supply: Experience steady power generation, regardless of variations in process steam demands, ensuring your operations run smoothly. Exceptional Versatility: Adapt effortlessly to your unique requirements, whether you need bleed or controlled extraction steams, with confidence in Kessels' expertise. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-42E Extraction Condensing Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

ET-30 Single Stage Steam Turbine

Single Stage Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Experience Unmatched Efficiency with Kessels ET-30 Single Stage Steam Turbine: Your Powerhouse for Precision In the world of industrial steam turbines, precision, reliability, and efficiency are non-negotiable. Kessels Steam Turbines is proud to introduce the ET-30 Single Stage Steam Turbine, a technological marvel that sets new standards in steam turbine excellence. Mastering Single Stage Steam Turbines Our Single Stage Steam Turbines are the embodiment of economy and reliability, serving as mechanical drives for Pumps, Fans, Knives, Compressors, and Generators. Over the past two decades, our engineering team has tirelessly reviewed customer and consultant requirements, meticulously addressing queries while adhering to the stringent standards of API 611 and 612. Unmatched Performance, Even at Low Pressure Kessels Steam Turbines have earned their stripes across diverse industries, renowned for their exceptional performance even under challenging low-pressure conditions. With over 15 frame sizes and design options, we offer Single Stage Steam Turbines capable of handling steam conditions and applications up to a staggering 4,000 HP in single-stage configurations. Industries Served Our Single Stage Steam Turbines find their utility across a spectrum of industries, including Oil and Gas, Food Processing, Chemical Processing, Pharmaceutical, Steel, Paper, Sugar, Palm Oil, Marine, Edible Oil, Rice, and Fertilizer. Versatility in Applications Kessels ET-30 Single Stage Steam Turbines can be seamlessly integrated into an array of applications, including Pump Drives, Fan Drives, Mill Drives, Generator Drives, Compressor Drives, Knives, and Shredder Drives. Power Capabilities Our turbines boast power capabilities ranging from 100 HP (75 kW) to a formidable 4,000 HP (3000KW), with speeds of up to 17,000 RPM. They can operate efficiently under pressures of up to 65 Kg/cm2 (925 Psig) and temperatures reaching 460°C (860°F). Design Versatility With seven distinct models, including Horizontal (axial and radial split), Vertical, API 611- and 612-compliant, Overhung, and between-the-bearings wheel designs, our turbines offer a range of options to suit your specific needs. Choose between metallic or carbon seals, Electronic/Hydraulic Mechanical governors, customized steam path components, Mechanical/Electronic safety trip systems, and Direct-Drive or integral gearboxes with suitable lubrication systems. Choose Kessels for Unrivaled Excellence Choosing Kessels Steam Turbines is a commitment to excellence, innovation, and reliability. Our ET-30 Single Stage Steam Turbine exemplifies these principles, offering you: Unmatched Efficiency: Harness the power of steam with unmatched efficiency, maximizing productivity while minimizing waste. Reliability Beyond Question: Crafted with precision and subjected to rigorous testing, our turbines ensure uninterrupted operations even in the most demanding industrial environments. Application Versatility: Adapt effortlessly to your unique requirements, confident that Kessels' expertise has you covered. Empower Your Future with Kessels In the competitive landscape of industrial steam turbines, every advantage counts. Step into a future of efficiency, reliability, and sustainability with the Kessels ET-30 Single Stage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-32 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Introducing the Kessels MS-32 Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the dynamic world of industrial steam turbines, efficiency, reliability, and flexibility are paramount. At Kessels Steam Turbines, we understand the unique needs of the oil and gas industry, where the demand for steam is relentless. That's why we are proud to introduce our MS-32 Multistage Steam Turbine – the pinnacle of back-pressure turbine technology. The Power of Back Pressure Turbines Back pressure turbines have long been a cornerstone of industrial steam applications, and they come in both single-stage and multi-stage options. These turbines serve as the vital link between the boiler unit and the process steam header. In environments where a copious amount of steam is required, back pressure turbines shine. Straight-Back Pressure for Maximum Efficiency What sets back pressure turbines apart is their straight-back pressure nature. This design allows for the efficient utilization of exhaust steam to meet process demands. The electrical power generated during the process is consumed precisely as needed, making it an energy-efficient choice. Applications Galore Our MS-32 Multistage Steam Turbine is a versatile powerhouse, ideally suited for a wide range of applications: Drive Applications: Commonly employed in the oil and gas industry, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and many more. Power Generation Applications: Utilized to generate electricity by powering generators, offering a clean and sustainable energy solution. Bleed Back-Pressure Steam Turbines For scenarios where controlled extraction of steam within a medium pressure range is necessary, our turbines come equipped with bleed points. This feature allows for steam extraction at low volume steam demands, making it perfect for applications with high tolerance for pressure variations. Extraction Back-Pressure Steam Turbines When the process steam demand volume is substantial, and tolerance for pressure variations is minimal, our steam turbines with controlled extraction vents step up to the plate. Operating under intermediate pressure levels, they ensure a consistent and reliable steam supply. Why Choose Kessels? When you choose Kessels Steam Turbines, you're choosing more than just a product – you're choosing a legacy of excellence. With a history spanning decades, we have continuously pushed the boundaries of steam turbine technology. Our MS-32 Multistage Steam Turbine is a testament to our unwavering commitment to innovation, performance, and customer satisfaction. Unmatched Benefits of the MS-32 Multistage Steam Turbine: Energy Efficiency: Our turbines maximize the use of exhaust steam, minimizing wastage and lowering energy costs. Reliability: Built with precision and rigorously tested, the MS-32 ensures uninterrupted operations, even in demanding environments. Versatility: From drive applications to power generation, this turbine adapts to your needs with ease. Eco-Friendly: Harnessing the power of steam for electricity generation reduces carbon emissions, contributing to a greener future. Responsive Support: Our team of experts is always at your service, ready to assist with installation, maintenance, and troubleshooting. Upgrade to Excellence Today In the competitive world of the oil and gas industry, every advantage counts. Make the smart choice by upgrading to the Kessels MS-32 Multistage Steam Turbine – the epitome of efficiency, reliability, and sustainability. Contact us today to learn more about how our turbine can revolutionize your operations and propel your success into the future. Your journey to unparalleled performance starts here, with Kessels Steam Turbines.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Elevate Your Operations with Kessels API-611 Compliant Steam Turbine: Where Precision Meets Excellence In the demanding realm of the oil and gas industry, precision, reliability, and adherence to standards are paramount. Kessels Steam Turbines takes pride in being a premier supplier of Steam Turbines that not only comply with but exceed the rigorous API-611 standards for general-purpose steam turbines. Setting New Standards in Steam Turbine Excellence Kessels Steam Turbines are at the forefront of driving pumps, fans, and compressors in Oil Refineries across the Middle East, India, and South East Asia. These turbines stand as testaments to our unwavering commitment to adhering to stringent design engineering practices set by oil giants and discerning end customers alike. Distinguishing Features of Kessels API-611 Single Stage Steam Turbines: Meets & Exceeds API-611 Standard: Our turbines not only meet but go beyond the API-611 standard, ensuring top-notch performance and reliability. Direct Drive Oil Relay Governors: Equipped with provisions for Direct Drive Oil relay constant speed governors conforming to NEMA class 'A' & NEMA class 'D'. Over Speed Mechanical Trip: Safety is paramount, and our turbines come with an over-speed mechanical trip with safety shut-off as standard. Versatile Gland Sealing: Gland sealing is achieved through carbon rings (up to six, removable), labyrinths, or mechanical steam seals. We offer the flexibility of choosing any combination of these three options. Impulse-Type Wheels: Provision for Single disc single-row, and Single disc two-row Curtis impulse-type wheels made of forged steel. Built-in Steam Strainer: As a standard feature, our turbines include a built-in steam strainer that is removable for your convenience. Versatile Support: Our turbines can be centerline or foot-mounted, offering flexibility in installation. Solenoid Trips: Provision for solenoid trips for remote shutdowns comes as standard, ensuring safety and control. Suitable for High Pressures: Built to handle high inlet and exhaust steam pressures, our turbines are robust and reliable. Horizontal and Vertical Orientation: Choose between horizontal and vertical shaft orientation to suit your specific needs. These features are a testament to our unwavering commitment to ensuring that customers can operate Kessels API-611 compliant Steam Turbines with complete peace of mind for their mechanical driving needs. Choose Kessels for Unparalleled Excellence Choosing Kessels Steam Turbines is a choice for excellence, precision, and reliability. Our API-611 Compliant Steam Turbines not only meet industry standards but surpass them, ensuring the highest levels of performance and safety for your operations. Empower Your Operations with Kessels In the competitive landscape of the oil and gas industry, precision and reliability are non-negotiable. Elevate your operations with the Kessels API-611 Compliant Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-42 EB Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. en New Delhi

Kessels Engineering Works Pvt. Ltd. en New Delhi

Unleash Power and Precision with the Kessels MS-42 EB Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the high-stakes world of the oil and gas industry, precision and performance are non-negotiable. That's why, at Kessels Steam Turbines, we're proud to introduce our cutting-edge MS-42 EB Multistage Steam Turbine – a powerhouse engineered to redefine excellence in back-pressure turbine technology. Mastering Back-Pressure Turbines Back pressure turbines have been the workhorses of industrial steam applications for decades, and our MS-42 EB takes their capabilities to new heights. Whether it's single-stage or multi-stage options, these turbines serve as the critical bridge between the boiler unit and the process steam header, revolutionizing steam utilization and power generation. Efficiency Redefined Our MS-42 EB Multistage Steam Turbine boasts the hallmark of back pressure turbines: their straight-back pressure nature. This design ensures the efficient harnessing of exhaust steam, meeting process demands with unparalleled precision. Every ounce of electrical power generated is consumed as per the process steam demand, offering unmatched efficiency. Applications Beyond Boundaries At Kessels, we understand that diverse industries have unique demands. That's why our MS-42 EB Multistage Steam Turbine excels in a wide range of applications: Drive Applications: Embrace the power of our turbine in oil and gas operations, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and more. Wherever drive power is needed, Kessels delivers. Power Generation Applications: Elevate your sustainability game by using our turbine to generate electricity, powering generators with clean and efficient steam energy. Bleed Back-Pressure Steam Turbines Our commitment to versatility is evident in the design of the MS-42 EB. With built-in bleed points, uncontrolled extraction vents enable steam extraction within a medium pressure range. This feature proves invaluable in situations where bleeding steam is required at low volume steam demands and when there's a high tolerance for pressure variations. Kessels turbines seamlessly blend the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines When your process steam demand volume is substantial, and you can't compromise on pressure variations, our steam turbines with controlled extraction vents come to the rescue. These turbines operate under intermediate pressure levels, ensuring a steady and reliable steam supply that your operations can depend on. Why Choose Kessels? Choosing Kessels Steam Turbines means choosing a legacy of excellence, innovation, and reliability. Our MS-42 EB Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization and minimize wastage with our precision-engineered turbine. Reliability Redefined: Rigorously tested and built with unwavering precision, the MS-42 EB ensures your operations run seamlessly. Unparalleled Versatility: Adapt to changing needs effortlessly, whether it's drive applications or eco-friendly power generation. Sustainability at Its Core: Harness the power of steam for electricity generation, reducing your carbon footprint and contributing to a greener future. Expert Support: Our team of specialists is always at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-42 EB Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you towards a future of success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

Unlock Energy Efficiency with Kessels API-611 Steam Turbine: The Ultimate PRV Replacement Solution In the dynamic world of industrial applications, energy efficiency is the cornerstone of sustainable operations. Kessels Steam Turbines is proud to offer a groundbreaking solution that replaces traditional Pressure Reducing Valves (PRV) with our robust, reliable, and highly efficient API-611 Steam Turbines. Revolutionizing Energy Efficiency Kessels Single Stage Steam Turbines are tailor-made to handle Saturated Steam at low inlet pressures, harnessing the pressure drop of steam to generate power through the turbine via geared or gearless Turbo Generator set solutions. Choice in Generators for Your Unique Needs Our Turbo Generator sets can be configured with either Induction Generators or Synchronous Generators, catering to the specific requirements of our customers. Energy Recovery at Its Best Kessels Industrial PRV replacement solutions are designed to recover wasted energy by reducing steam pressure through our steam turbines, surpassing the limitations of traditional PRVs. This not only generates valuable power for industrial use but also caters to the process steam requirement of the industry. The result? Drastically reduced operational costs and reduced reliance on the grid and other more expensive power sources. Balancing Act: PRV and Power Generation Kessels Single Stage Steam Turbines are ingeniously designed to enable customers to enjoy the full benefits of a PRV system while simultaneously generating useful power. This equilibrium is achieved without compromising the stability or safety of the system or their setup. Maximizing Power Output For optimum performance, Kessels offers the option of Multiple Valve Operated Steam Turbines. These turbines ensure customers get maximum power output, even at partial loads and varying steam flows. Our valves, available in the Single Stage Steam Turbine range, can be controlled automatically through the special PLC-based governing system provided by Kessels for turbines coupled to Induction Generators. Versatile Powerhouses Kessels API-611 Steam Turbines are versatile, highly efficient, rugged, and robust. They boast single disc one-row and two-row Curtis impulse-type wheels, making them suitable for a wide range of industrial applications. Additionally, these turbines can be retrofitted to any existing boiler setup, making them a versatile choice for various installations. Key Features: Versatile and highly efficient. Single disc one-row and two-row Curtis impulse-type wheels. Retrofittable to existing boilers. Operates efficiently with high exhaust steam pressures. PLC-based control panel with HMI screen for ease of use (optional). Compatible with both Induction and Synchronous Generators. Operates in solo mode or synchronized mode. Can be synchronized with the grid and/or other power sources. Reduces operational costs with a short payback period. Quick startup times and option for complete automatic operation. Choose Kessels for a Sustainable Future Elevate your industrial operations with the Kessels API-611 Steam Turbine, the ultimate PRV replacement solution that combines energy efficiency, reliability, and versatility. Contact us today to discover how our turbine can revolutionize your energy management and lead you toward unprecedented success.

Envío:

Situado en:

India

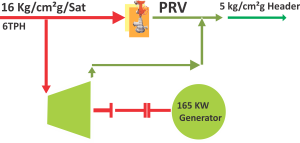

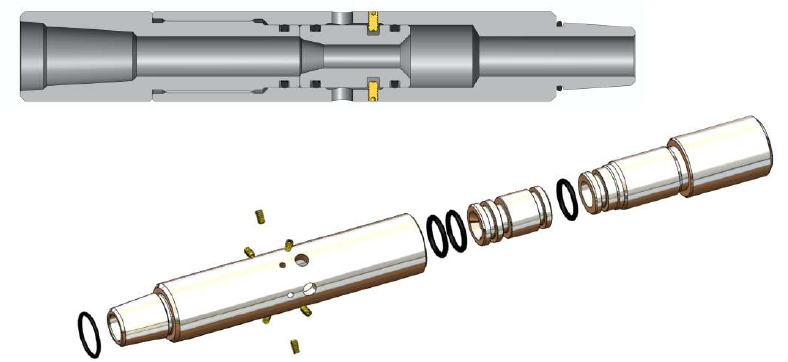

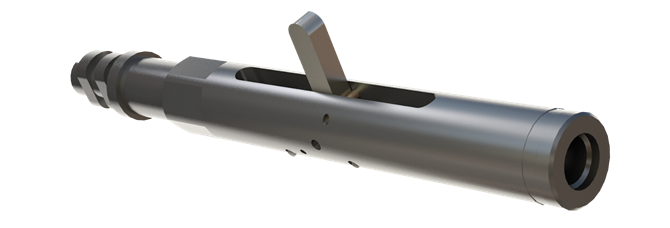

Coiled Tubing Hydraulic Vibration Tool

HVT Coiled Tubing Tool![]() Marlin Oil Tools en Calgary

Marlin Oil Tools en Calgary

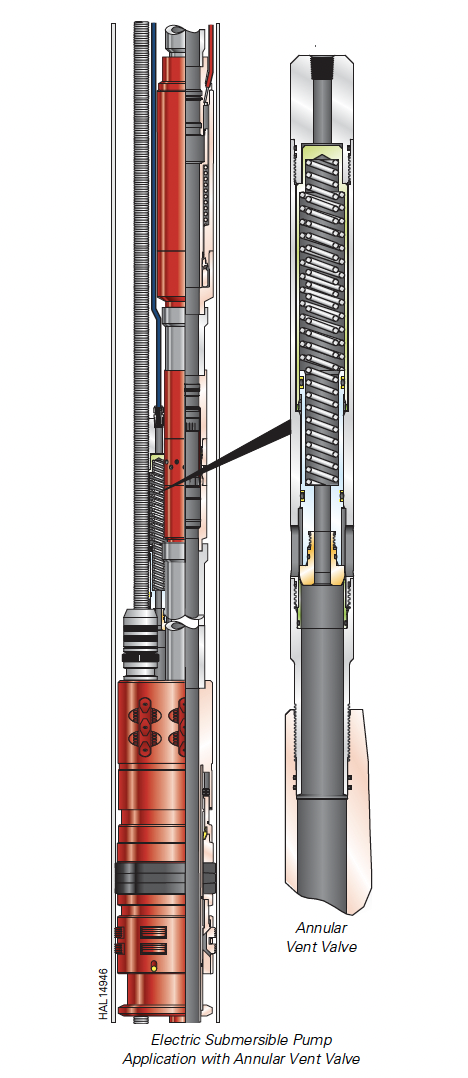

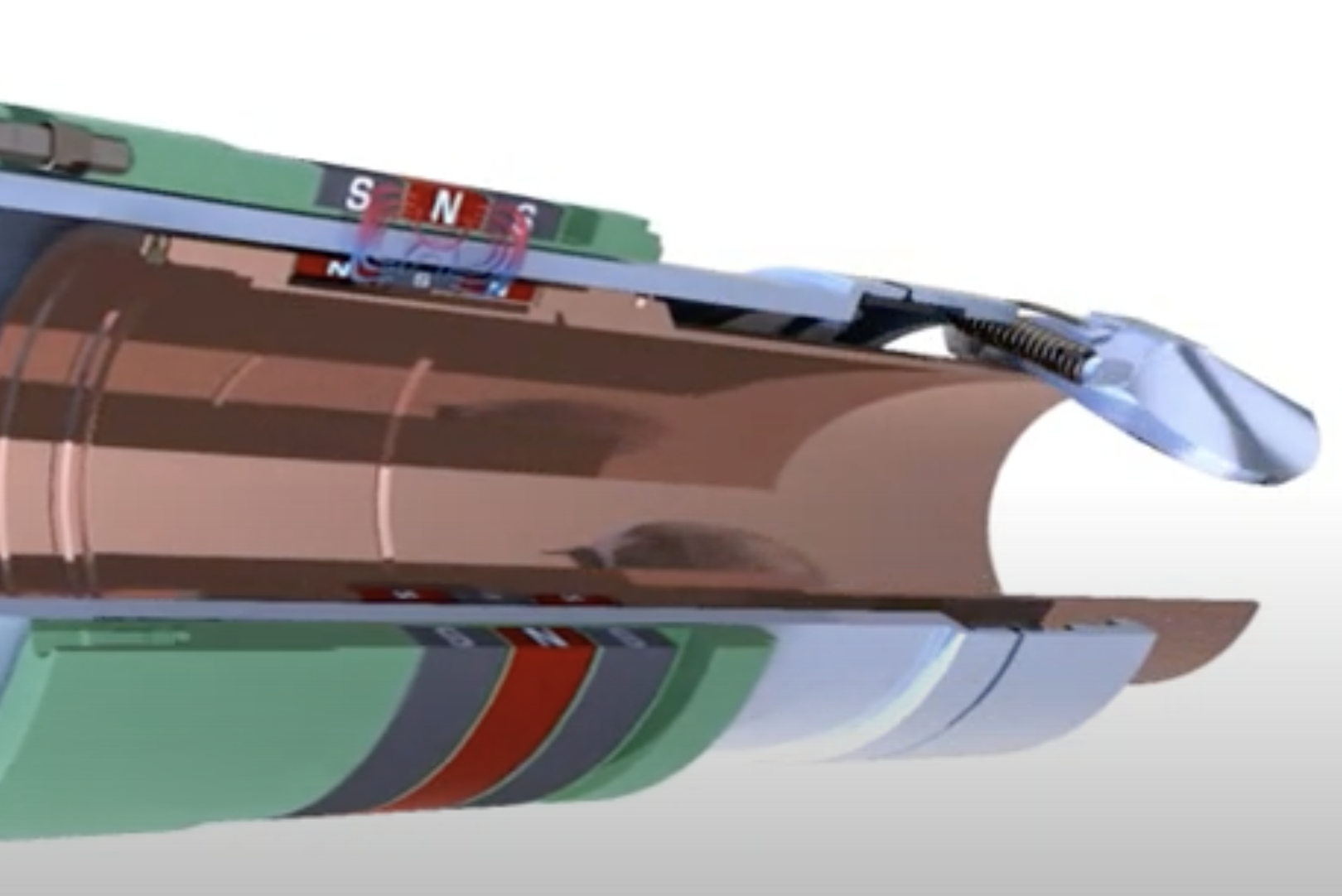

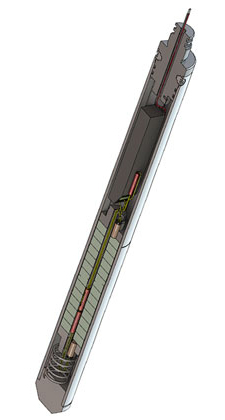

Introducing the HVT (Hydraulic Vibration Tool) from Marlin Oil Tools: Revolutionizing Well Intervention and Completion Operations Marlin Oil Tools is proud to present the HVT (Hydraulic Vibration Tool), an advanced downhole tool designed to significantly enhance the efficiency and reach of well intervention and completion operations. The HVT stands out for its ability to create controlled vibrations when liquid is pumped through it, reducing the friction coefficient across the Bottom Hole Assembly (BHA) and ensuring extended reach in long horizontal wells. Here’s a closer look at the HVT’s features, benefits, and why it’s an essential tool for your oil and gas operations. Key Features of the HVT (Hydraulic Vibration Tool): Friction Reduction: The HVT generates vibrations that significantly reduce the friction coefficient, facilitating smoother and longer reach of the BHA in horizontal wells. Versatile Application: With options for larger diameters, the HVT can also be utilized as part of the casing shoe, ensuring that the casing reaches the planned depth during well completions. Exceptional Durability: Engineered to withstand harsh downhole conditions, the HVT is resistant to nitrogen, acid, and hydrogen sulfide, offering unlimited working time in challenging environments. Compact and Efficient: The tool’s short length makes it an ideal choice for operations requiring high maneuverability and efficiency. Elevate your well intervention and completion processes with the HVT (Hydraulic Vibration Tool) from Marlin Oil Tools, a cutting-edge solution designed to overcome the challenges of extended reach in horizontal wells. By creating controlled vibrations, the HVT reduces friction, enhancing BHA maneuverability and ensuring casing is accurately placed during well completions. Its resistance to nitrogen, acid, and hydrogen sulfide guarantees reliability in even the most demanding environments, while its compact design promotes operational efficiency. Choose the HVT for unparalleled performance and durability in your oil and gas operations. Why Choose the HVT from Marlin Oil Tools? Enhanced Operational Reach: Maximizes the effectiveness of well interventions in horizontal sections. Increased Completion Success: Assists in achieving accurate casing placement for optimal well completions. Reliable in Harsh Conditions: Offers unmatched durability against nitrogen, acid, and hydrogen sulfide. Streamlined Design: Facilitates ease of use and integration into existing operations without extensive modifications. The HVT (Hydraulic Vibration Tool) by Marlin Oil Tools represents the forefront of innovation in downhole tool technology, providing operators with a powerful solution to enhance the reach and success of well interventions and completions. Incorporate the HVT into your toolkit to achieve operational excellence and maximize the potential of your oil and gas wells.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() InWaTec Combined en Vechta

InWaTec Combined en Vechta

Revolutionizing Geothermal Well Interventions: InWaTec Combined's Mini-Coil Services In the dynamic world of geothermal energy production, where the efficient management of well interventions is paramount, InWaTec Combined is pioneering with our Mini-Coil Services. Designed to navigate the unique challenges of geothermal wells, our Mini-Coil Tubing offers a versatile and high-pressure tolerant solution for fluid placements and well stimulation. Geothermal wells demand a delicate balance between precision and strength. Our Mini-Coiled Tubing services are tailored to meet these needs, providing an ideal solution for the small quantity placements of fluids that are often required in geothermal operations. Whether it's for precision acidizing, scale removal, or other chemical treatments, the Mini-Coil is an invaluable tool. Compact Power: Our Mini-Coiled Tubing is compact yet robust, designed to handle the high pumping pressures needed for effective interventions in geothermal wells. Its smaller diameter does not compromise its ability to withstand intense conditions underground. Efficiency in Production: Lifting wells into production efficiently is crucial for maintaining the economic viability of geothermal operations. The Mini-Coil facilitates this by enabling operators to deliver targeted treatments and interventions that can revitalize well performance. Tailored to Geothermal Needs: While traditional coiled tubing operations may be limited by flow and snubbing capabilities, our Mini-Coil Tubing is engineered to overcome these constraints, providing enhanced pressure handling that is especially beneficial in the high-temperature, high-pressure environments characteristic of geothermal wells. It's true that Mini-Coil Tubing has its limitations regarding flow and snub, but what it offers in return is the capacity to handle significantly higher pumping pressures. This attribute is particularly advantageous in geothermal applications where the subsurface conditions can be extreme. InWaTec Combined's commitment to innovation is further demonstrated by the integration of advanced monitoring technologies that accompany our Mini-Coil Services. Real-time data acquisition allows for precise control and assessment of the intervention process, ensuring that operations are not only successful but also conducted with an emphasis on safety and sustainability. In the realm of geothermal energy, where the right interventions can drastically enhance the output and longevity of wells, InWaTec Combined's Mini-Coil Services emerge as a clear choice for operators seeking to optimize their wells. Our services are a testament to our dedication to providing solutions that are both efficient and effective, reducing downtime and maximizing production. Partner with InWaTec Combined for your geothermal well needs and experience the next level of well intervention services. Let our Mini-Coil Tubing unlock the full potential of your geothermal operations, where precision meets power, and innovation drives production.

Service

In Stock

Service

New

API

Land Freight

![]() AMS Hydro en Vancouver

AMS Hydro en Vancouver

A SIMPLE WATER-TO-WIRE SOLUTION This micro hydro solution is based on both proprietary designs in the turbine and drivetrain, and off-the-shelf components, to deliver a complete water-to-wire system. This solution is a self-contained module made of single or twin turbines, generators, electrical cabinet, and is connectable to BOP/Grid. They are assembled and mounted in a self-stabilized concrete structure requiring no civil works. The system power output is 480 V, 3-phase AC, 50 Hz & 60 Hz. This new, highly cost-effective, renewable energy solution, capable of capturing most of the untapped energy on your site, has many assets. Its performance levels have been tested both in laboratory and on site. Actual power rating and instantaneous output depend mainly on water velocity (>1 m/s). In our catalogue of product, we can select the best options to suit a particular site. This technology is scalable by equipping an existing canal with dozens or hundreds of 5 to 15 kw modules. Land usage Turbines are installed on existing, untapped water infrastructures. No land planning is needed, with no modification required on existing assets. Predictable and available Permanent, predictable and controllable production with 95% availability. *information from manufacturer

Buy

Made to Order

Product

New

ASTM

Land Freight

Partnered with Microsoft Business Voice

Cybersecurity![]() ALCiT en Mississauga

ALCiT en Mississauga

Elevate Your Communications with ALCiT's Microsoft 365 Business Voice Partnership In the world of innovation, one name shines brighter than the rest: Microsoft. Since its inception in 1975, Microsoft has been synonymous with technological prowess, transforming the landscape of modern business. ALCiT proudly joins forces with Microsoft 365 Business Voice, introducing a cloud-based, integrated phone system that redefines how you communicate, collaborate, and connect. Microsoft: A Legacy of Innovation Microsoft's legacy is etched in innovation. For decades, they've sculpted the digital future, revolutionizing industries and empowering businesses. ALCiT is thrilled to be a part of this legacy, bringing you Microsoft 365 Business Voice – a solution that transcends communication barriers. Resource Unification, Powered by the Cloud Imagine a realm where your resources converge seamlessly. With Microsoft 365 Business Voice, you can bid adieu to scattered communication tools. This cloud-based, integrated phone system places your entire arsenal in one place, fostering collaboration and calling no matter where you work. Effortless Communication, Elevated Flexibility ALCiT's Microsoft 365 Business Voice empowers you in two pivotal ways: Customer Connection Amplified: Responding to customers becomes a breeze, with unmatched ease and flexibility. Answering the phone transforms from a task into a seamless interaction. Infinite Collaboration: Breaking boundaries within your team and business is no longer a challenge. Seamlessly communicate, collaborate, and create, regardless of physical barriers. Grow with Confidence Designed with small-to-medium businesses in mind, Microsoft 365 Business Voice is your compass to growth. ALCiT's partnership ensures that the system is not just a tool, but an engine of expansion, enabling businesses to rise to new heights. Shape the Future of Communication Today ALCiT's Microsoft 365 Business Voice partnership redefines communication. Experience the cloud-based revolution that connects you with your customers, your team, and your growth journey. Experience the power of ALCiT's partnership with Microsoft 365 Business Voice.

Service

Made to Order

Service

New

ISO

![]() Marlin Oil Tools en Calgary

Marlin Oil Tools en Calgary

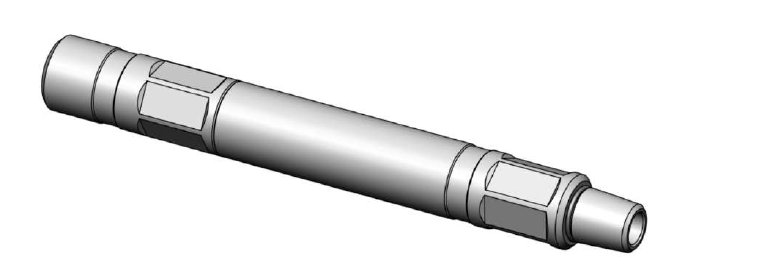

Introducing the JKM Junk Mill from Marlin Oil Tools: The Ultimate Downhole Tool for Efficient Well Intervention and Milling Operations Marlin Oil Tools proudly presents the JKM Junk Mill, a premier downhole tool designed to optimize well intervention jobs by efficiently grinding and removing unwanted objects from the wellbore. Whether you're dealing with intentionally placed equipment such as bridge plugs or facing challenges with emergency lost equipment, the JKM Junk Mill is engineered to handle a variety of downhole obstacles with unmatched efficiency. Key Features of the JKM Junk Mill: Superior Milling Performance: Capable of grinding and washing out any object softer than the mill's cutters, ensuring clean and clear wellbores. Effective Debris Removal: Features multiple flushing holes for drilling fluid circulation, efficiently removing milled particles and cooling the cutting edge. Durable Carbide Construction: Equipped with carbide welded onto the body for robust milling action, available in crushed carbide and various insert designs to suit different milling needs. Customizable Milling Solutions: Offers a range of carbide welding designs including flat, concave, and convex bottoms, as well as top and side carbide surfacing, providing versatility for specific well intervention requirements. Extended Service Life: The durability of the carbide elements depends on the milling conditions, with Marlin Oil Tools providing redress services for worn carbide to ensure continued high performance. Powered by Downhole Motors: Rotation of the mill is performed by a downhole motor, enhancing milling efficiency and effectiveness. Elevate your well intervention strategies with the JKM Junk Mill from Marlin Oil Tools, a cutting-edge solution designed for the efficient removal of downhole obstacles in the oil and gas industry. Featuring advanced milling capabilities, effective debris removal, and durable carbide construction, the JKM Junk Mill ensures your wellbore is free from unwanted materials, enhancing operational efficiency and well productivity. With customizable carbide designs and comprehensive redress services, Marlin Oil Tools provides a versatile and reliable tool for tackling a wide range of milling challenges. Choose the JKM Junk Mill for its superior performance, durability, and adaptability, making it an essential component of your well intervention toolkit. Why Choose the JKM Junk Mill from Marlin Oil Tools? Enhanced Milling Efficiency: Delivers unparalleled performance in grinding down and removing wellbore obstructions. Versatile Application: Adaptable to various well intervention scenarios, from routine cleanouts to emergency equipment retrieval. Long-Term Durability: Constructed with high-quality carbide for extended tool life, even in the most challenging milling operations. Tailored to Your Needs: Offers customization options to match your specific well intervention requirements, maximizing tool effectiveness. The JKM Junk Mill by Marlin Oil Tools represents the forefront of downhole milling technology, offering oil and gas operators a powerful solution for enhancing well intervention outcomes. Incorporate the JKM Junk Mill into your operations for smoother, more effective wellbore preparation and obstacle management.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Energy Distribution Management

Software Development![]() Eleks en Toronto

Eleks en Toronto

ELEKS: Powering the Future of Efficient Energy Distribution Management Harness the power of technology to revolutionize energy distribution management with ELEKS. Our expertise in energy software development brings stability, accessibility, cleanliness, and sustainability to your consumers while ensuring the resilience of your networks against challenges and threats. As a leading energy software company, we're at the forefront of developing and integrating Custom Distribution Management Systems (ADMS) that empower utility suppliers to meet customer demands for power quality, reliability, and data security. Elevate Your Energy Management with ELEKS Energy Software Development: Embrace the future of energy management with our advanced software solutions. Dramatically enhance productivity, accessibility, safety, and sustainability in your business power system. Join the ranks of forward-thinkers who are leveraging technology to redefine the energy landscape. Empowering Energy Producers and Distributors: Customized Solutions for You: As a seasoned custom software development company, ELEKS has been empowering energy producers, distributors, smart city developers, and governmental organizations for three decades. Our expertise lies in crafting tailored data-driven software solutions and energy management systems that leverage cutting-edge technologies such as Cloud, IoT, blockchain, and drones. Unveiling the Future of Energy Management: Understanding Your Needs: We comprehend the intricacies of the energy and utility industry – from modern power management solutions for diverse sources to facilities and businesses. Our journey has been marked by refining our understanding of unique industry challenges and leveraging technology to develop innovative solutions. Why Choose ELEKS? Experience That Matters: With a legacy spanning thirty years, ELEKS brings a wealth of experience to the table. Our team of experts is well-versed in addressing complex energy management challenges. Cutting-Edge Technologies: Our energy software development solutions are fueled by the latest technologies, including Cloud, IoT, blockchain, and more. Stay ahead of the curve and embrace the future with confidence. Empower Efficiency and Sustainability: Energy efficiency and sustainability aren't just buzzwords – they're critical factors in a changing world. ELEKS' solutions empower you to meet these demands head-on. Join the Energy Revolution with ELEKS Revolutionize the energy distribution landscape and empower efficient energy management with ELEKS. Our energy software development solutions are designed to catapult your business into a future of resilience, reliability, and sustainability. Embrace innovation – choose ELEKS to lead the way into a brighter, greener future.

Service

In Stock

Service

New

ISO

![]() Midastream Supply Company en Airdrie

Midastream Supply Company en Airdrie